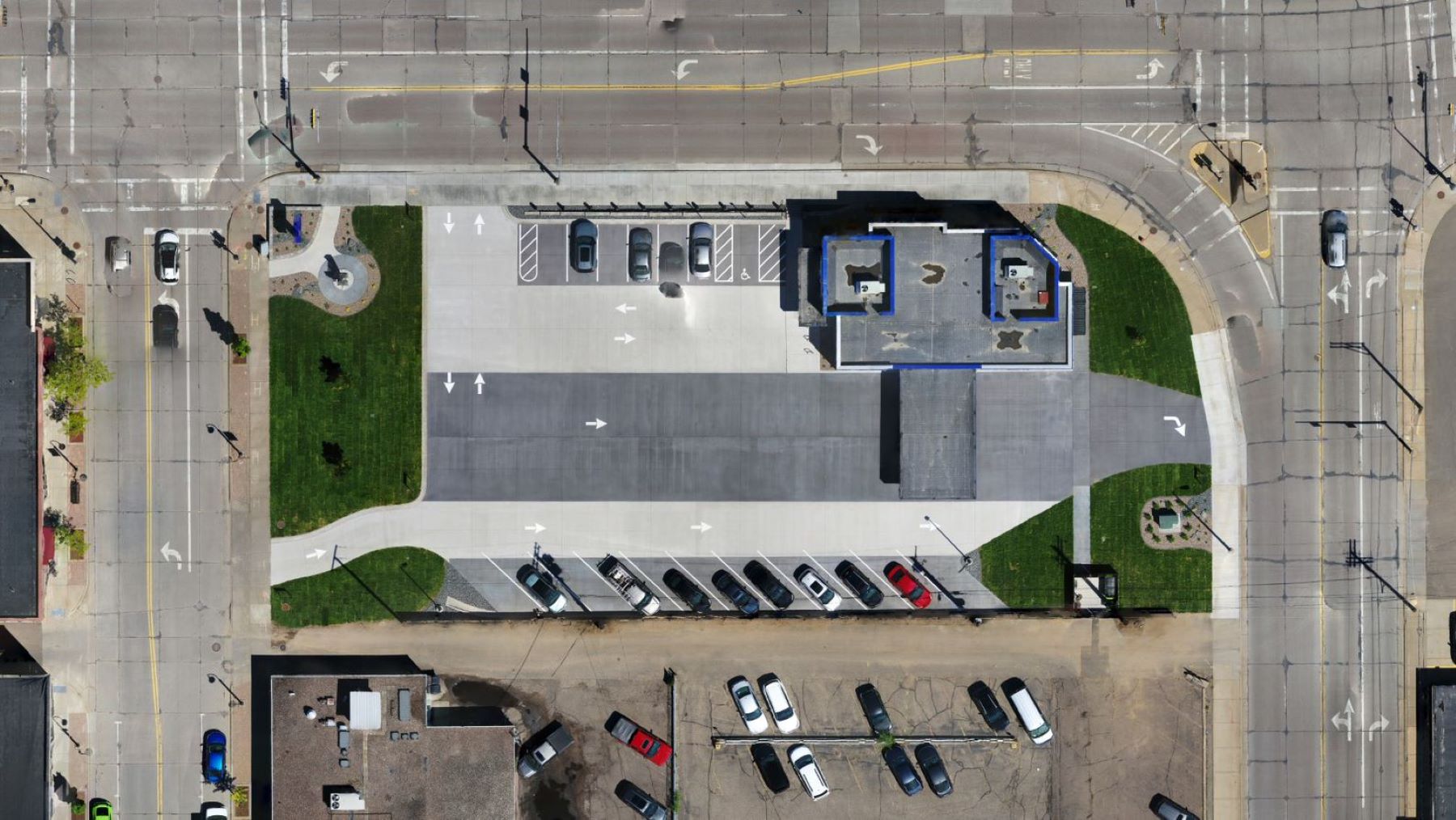

Environmental Advantages

Concrete Parking Lots have many environmental benefits, including:

- Durable - Concrete stands up to natural disasters, wind-driven rain, moisture damage, and vermin. Less replacement means reduced resource requirements.

- Cool - Using light or natural-colored material helps reduce the heat island affect.

- Recyclable - At the end of its service life, concrete is commonly recycled into fill and road base materials.

- Local Materials - Materials are usually extracted and manufactured locally.

- Recycled Content - Fly ash, slag cement, or silica fume can substitute partially for cement, and recycled aggregates can replace newly mined gravel.

Enhance your Wisconsin parking lot projects by incorporating the dynamic world of colors and textures into your parking applications.

Textures or Exposed Aggregate Concrete

An exposed aggregate finish softens the look of traditional concrete. Texture is achieved by brushing and washing away surface mortar as the concrete begins to harden, so the stone or gravel in the concrete becomes visible. Any attractive stone can be imbedded into the surface - marble, granite chips, pebbles ... even shells.

Patterns or Stamped Concrete

Semi-hardened concrete can be pattern-stamped with special tools to create the custom look and feel of slate, cobblestone, brick, or tile. The patterns can help scale down large expanses of paving or provide a special elegance for employees and customers.

Colors

Concrete can be cast in a wide variety of colors. Pastels and earth tones are produced by mixing mineral pigments throughout the concrete. For deeper tones, concrete finishers use the dry shake method - sprinkling powdered, prepackaged color-hardeners onto a freshly cast concrete slab, then trowelling it into the surface.

Variations in the color and texture of concrete surfaces are limited only by the imagination of the designer and the skill of the concrete craftsman.